Slip resistance testing for sports floors is the method used to measure the traction of an indoor sports surface. Usually this will be carried out on a sports hall floor to ensure that it is safe for sporting use. Since adults or children will be using sports areas for high-activity games where running and jumping will be involved, it is essential that the floor has the correct level of traction. This will keep everyone using the area safe, minimising the risk of injury.

The Pendulum Slip Resistance Test (BS7976) is a procedure that is recognised by Health and Safety Executives (HSE) and should be carried out annually. Our team can offer this test to you as part of your installation or refurbishment with us or for an existing floor.

Get in touch today to find out more about slip resistance testing.

Pendulum Slip Resistance Tests are essential for any flooring company that is concerned with user safety. Slips and falls are a significant cause of accidents in various settings, often leading to injuries and potential legal liabilities. Conducting these slip tests allows companies to identify hazards and take measures to mitigate them, ensuring that their flooring products comply with safety standards.

The results of these tests are crucial not only for legal compliance but also for enhancing customer trust. When Courtship Flooring provides sports hall flooring options tested for slip resistance, it demonstrates a commitment to quality and safety, a factor that differentiates the company in a competitive market. Different environments require specific levels of slip resistance, and Pendulum Slip Resistance Tests enable companies to classify flooring surfaces appropriately, ensuring the right product is selected for each location.

Other important factors include:

Pendulum Slip Resistance Tests are a vital component in assessing the safety and functionality of flooring solutions, especially in areas where there is a risk of slipping. For Courtship Flooring, understanding these tests is essential for delivering products that meet both aesthetic and functional requirements while also ensuring the safety of users. This comprehensive guide explores the mechanics, significance, and applications of Pendulum Slip Resistance Tests within the flooring industry, offering essential insights for professionals and customers.

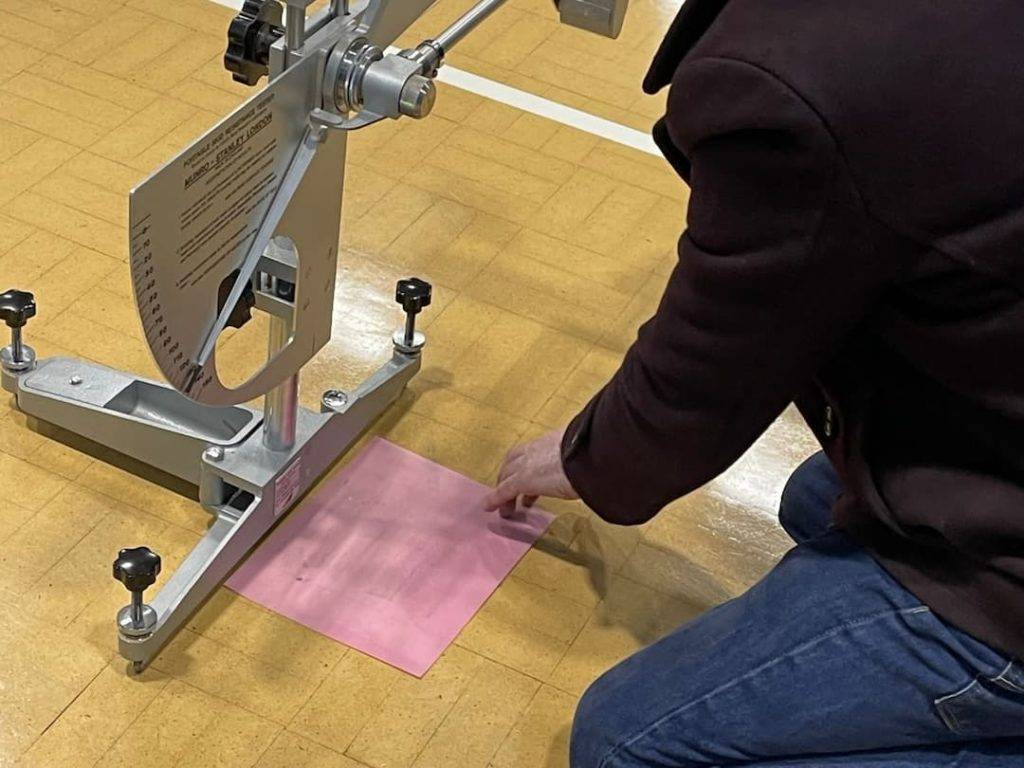

The Pendulum Slip Resistance Test apparatus consists of a swinging arm, or pendulum, fitted with a rubber slider. The testing process starts with preparing the surface by cleaning and drying it, or by wetting it to simulate real-world conditions, depending on the intended usage of the flooring. The pendulum device is then positioned over the surface to ensure that the rubber slider contacts the floor during the swing. The rubber slider, made from a standardised rubber material such as Four S or TRL rubber, is adjusted to strike the surface at a precise angle and pressure. As the pendulum swings across the surface, the resistance encountered slows it down, and this deceleration is recorded as the Pendulum Test Value (PTV). A PTV below 25 indicates a high slip potential, values between 25 and 35 suggest moderate slip potential, while a PTV above 36 represents low slip potential, signifying a safer surface.

Several factors can influence the outcome of a Pendulum Slip Resistance Test, and these must be carefully managed to ensure reliable results. The condition of the surface, whether dry, wet, or contaminated with substances like oil, grease, or dirt, can significantly impact the slip resistance results. Testing surfaces in conditions that replicate their intended real-world usage is a common practice. The type of rubber used for the slider also plays a role, with Four S rubber typically used for dry and lightly wetted conditions, while TRL rubber is used for more heavily contaminated surfaces. The location of the test is important, as multiple testing points across the floor help account for variations, especially where there are differences in surface texture or treatments. Temperature and humidity are also factors to consider, as they may affect the properties of both the rubber slider and the floor surface, making it crucial to perform tests under consistent conditions for comparative purposes.

Pendulum Slip Resistance Tests are crucial across a range of settings where flooring safety is a priority. In commercial spaces such as offices, retail stores, and public buildings, where foot traffic is high, it is important to ensure the flooring minimises slip risks. Pendulum testing helps verify that the flooring in these environments is safe for daily use, reducing the likelihood of incidents. In areas like court flooring, sports hall flooring, swimming pools, and changing rooms, which are prone to wet conditions, there is an increased slip risk that necessitates flooring with higher Pendulum Test Values to provide sufficient resistance. In healthcare settings such as hospitals and care homes, where many users are vulnerable, Pendulum Slip Resistance Tests help ensure that the flooring meets stringent safety standards, reducing the risk of falls for both patients and staff.

Industrial environments often involve exposure to oils, chemicals, or other substances that can make floors slippery. Slip resistance testing helps identify the most suitable flooring solutions for these settings, ensuring that the products can endure the conditions while maintaining safety standards.

Pendulum Slip Resistance Tests are an essential tool in the sports flooring industry, particularly for companies committed to providing sports flooring solutions that prioritise safety and quality. By carefully considering the factors that influence test results and adhering to best practices, this testing method serves as a powerful means of reducing slip risks and enhancing the overall safety of flooring installations. For a company like Courtship Flooring, leveraging Pendulum Slip Resistance Tests helps ensure that each flooring product meets the highest standards of safety, thereby enhancing the wellbeing of users and minimising the potential for accidents.

The use of Pendulum Slip Resistance Tests not only helps to ensure legal compliance but also reflects a company’s commitment to quality and customer safety. For Courtship Flooring, using this test represents a proactive approach to providing clients with sports flooring solutions that offer peace of mind and reliable performance across a wide range of environments.

YES!, slip resistance testing is an important part of compliance with health and safety regulations in many industries. Employers and property owners have a duty to provide a safe environment, and slip resistance testing is a recognised way to assess and mitigate slip risks. In some sectors, such as healthcare or public facilities, compliance with slip resistance standards is more strictly regulated.

Slip resistance testing is a process used to measure the frictional properties of a floor surface to assess the likelihood of slipping. It evaluates how a surface interacts with a person’s footwear or bare feet under different conditions, such as dry, wet, or contaminated, and provides a quantitative measure of the surface’s safety.

Slip resistance testing is crucial for ensuring the safety of floor surfaces in various environments. Slips and falls are common causes of injuries, and testing helps to identify potential hazards. The results can guide the selection of suitable flooring materials for different areas and ensure compliance with safety standards and regulations. It also helps reduce liability risks for property owners and businesses.

The Pendulum Slip Resistance Test is a widely accepted method for measuring slip resistance. It uses a swinging arm (pendulum) with a rubber slider attached, which simulates the action of a shoe heel striking the floor. As the pendulum swings across the surface, the resistance encountered is measured and recorded as the Pendulum Test Value (PTV). This value indicates the slip resistance of the surface, with higher values representing greater slip resistance.

In the UK, slip resistance testing is commonly carried out according to British Standards (BS 7976: Parts 1-3, 2002) using the Pendulum Slip Resistance Test. A Pendulum Test Value (PTV) of 36 or higher is considered to represent a low slip potential, while values between 25 and 35 indicate moderate slip potential. A PTV below 25 is classified as a high slip potential, meaning the surface may pose a significant slip risk.

Several factors can influence the results of slip resistance tests, including the surface condition (dry, wet, or contaminated), the type of rubber slider used (Four S or TRL rubber), the angle of the surface, and environmental factors such as temperature and humidity. Testing in various locations on the floor can also reveal differences in slip resistance across different sections.

The Pendulum Slip Resistance Test is performed by positioning the pendulum device over the floor surface. The rubber slider attached to the pendulum swings across the surface, simulating a heel strike. The resistance encountered by the slider causes the pendulum to slow down, and this deceleration is recorded as the Pendulum Test Value (PTV). The test can be conducted on both dry and wet surfaces to assess the slip resistance under different conditions.

Yes, slip resistance tests can be conducted on wet floors to simulate conditions where water or other liquids may be present. Testing on wet surfaces is crucial in environments such as bathrooms, kitchens, and outdoor areas where surfaces are frequently exposed to moisture. It helps ensure that the flooring provides adequate slip resistance even when wet.

The frequency of slip resistance testing depends on factors such as the type of environment, the level of foot traffic, and the risk of surface contamination. For high-risk areas, such as industrial settings or wet areas, more frequent testing may be necessary. Routine testing helps ensure ongoing compliance with safety standards and the maintenance of safe flooring conditions.

Yes, there are methods to improve slip resistance after flooring installation. This can include applying anti-slip treatments, using slip-resistant coatings, or installing mats or tapes in high-risk areas. Regular cleaning and maintenance can also help maintain or improve slip resistance by removing contaminants that reduce friction.

A low Pendulum Test Value (PTV), typically below 25, indicates a high slip potential. This means that the surface may be prone to slipping, especially under wet or contaminated conditions. In such cases, additional measures may be necessary to improve the slip resistance of the floor or to restrict access to areas where there is a higher risk.

By conducting slip resistance testing, property owners and businesses can identify areas of high slip risk and take appropriate action to mitigate hazards. This proactive approach not only ensures compliance with safety standards but also helps to reduce the likelihood of accidents and liability claims arising from slip-related incidents

If a floor fails a slip resistance test, steps can be taken to improve safety. This may include applying anti-slip coatings, installing slip-resistant mats, using textured flooring materials, or implementing regular cleaning to remove contaminants. In some cases, resurfacing or replacing the floor may be necessary to achieve the desired slip resistance level.

Slip resistance testing should be conducted by Courtship Flooring who are trained professionals who understand the testing standards and have the appropriate equipment. Certified testing services can provide accurate and reliable results, ensuring that flooring meets the necessary safety standards.

Get in touch with our team for a slip resistance test to be carried out in your premises.